As a kind of brazing material, aluminum brazing ac coil has a melting point above 450°C, and the brazing temperature is usually selected to be 25°C-60°C higher than the liquidus temperature of the solder to ensure that the solder can fill the gap....

As a kind of brazing material, aluminum brazing ac coil has a melting point above 450°C, and the brazing temperature is usually selected to be 25°C-60°C higher than the liquidus temperature of the solder to ensure that the solder can fill the gap. The load-bearing capacity of brazing joints is related to the size of the joint connection surface. Therefore, brazing generally uses lap joints and kit inlays to make up for the lack of brazing strength.

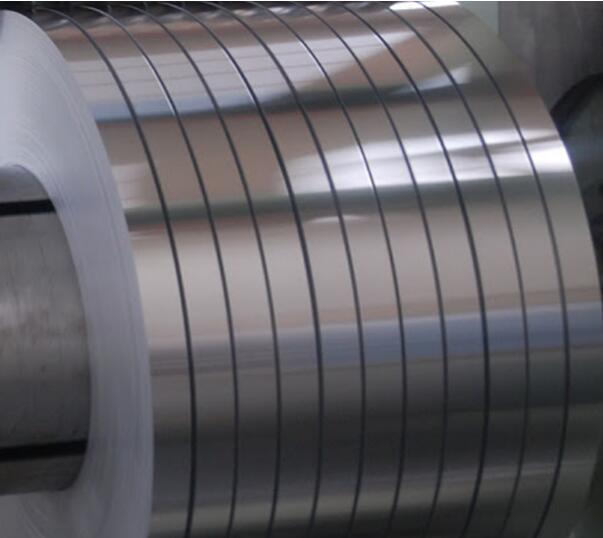

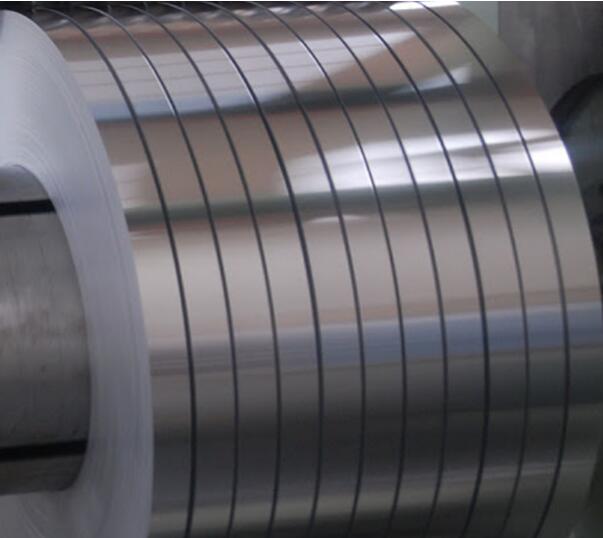

The joint strength of the aluminum brazing ac coil is high, the heat resistance is good, and it can work at high temperatures. The brazed brazing ac coil produced by our company mainly include 3 series and 4 series products, such as brazing ac coil such as 3003, 3103, 4004, etc., which are often used in the field of oxygen production equipment and radiators for the automotive industry. All kinds of brazed brazing ac coil produced adopt the world-class advanced equipment such as German Luke spectrometer, Hitachi scanning electron microscope and energy spectrometer, American thermoelectric spectrometer, etc. to ensure the fine quality of the products. The products produced are beautiful and smooth, with bright colors and no cracks on the surface. Seamless welding can be ensured during welding, with good fluidity during welding and no bubbles.

Performance advantages of our company's aluminum brazing ac coil:

A: High strength and excellent welding performance.

B: Good heat resistance and high temperature resistance, and a certain degree of corrosion resistance.

C: Excellent processing performance, small changes in structure and mechanical properties, small deformation, and easy molding.

D: The product is beautiful, there are no pores, cracks, weld bumps and other phenomena in the welding. The surface of the weld joint is bright and the fillet is even.

Technical parameters of brazing aluminum sheet

Alloy Series Typical Alloy Material State Thickness (mm) Width (mm) Length (mm)