...

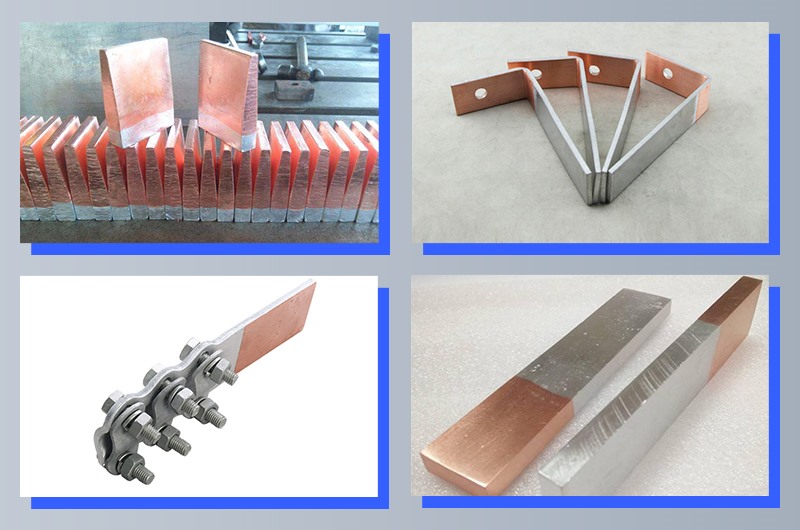

Introduction of brazing process of 6063 aluminum alloy and red copper joint

Aluminum and copper are widely used in the fields of electricity transmission, heat exchange and daily necessities because of their good electrical and thermal conductivity. In comparison, the conductivity and thermal conductivity of aluminum are not as good as that of copper, while the market price of aluminum is 1/3 of that of copper, and the density of aluminum is only 1/3 of that of copper. Without considering the mechanical properties and electrothermal properties, the cost of aluminum materials for the same components is 1/9 of that of copper materials. Therefore, many industries adopt the technology of "replacing copper with aluminum" to reduce production costs, such as the preparation of microelectronic devices, energy equipment, hybrid vehicle batteries and energy batteries. There are many methods of aluminum copper connection. Starting from different aspects such as technology and materials, melting welding and brazing can be used. Among them, melting welding aluminum / copper joint has high production efficiency and beautiful forming, but the joint is brittle, low strength and easy to crack; On the premise of strictly controlling the solder composition and brazing process, the copper / aluminum joint with excellent performance can be obtained. Therefore, brazing is a promising copper aluminum connection technology.

Brazing process of 6063 aluminum alloy and red copper joint

In order to realize the efficient connection of 6063 aluminum alloy / red copper joint, the materials we use are 6063 aluminum alloy and red copper. The solders are zn75al25 and zn92al8 zinc aluminum flux cored welding wires respectively, as well as the corresponding zinc aluminum solid core solder. The flux is csf-alf3 medium temperature non-corrosive flux. The flame is used as the heat source and the operation method of TIG welding is adopted.

In traditional brazing, the solid solder and CSF AlF3 medium temperature non-corrosive flux is first laid on the edge of the lap joint, and then placed in the resistance furnace for heating. The new brazing process uses flux cored brazing wire as the welding material, scientifically proportioning the amount of flux and filler metal, using LPG flame as the heat source and the operation method of tungsten argon arc welding. Because the medium temperature non-corrosive flux of csf-alf3 is wrapped in the core of the welding wire, the wire filling and flux addition are carried out simultaneously, which is convenient to operate and high production efficiency.

Features of brazing process of 6063 aluminum alloy and red copper joint

1) Compared with the joints brazed in the traditional furnace, the 6063 aluminum alloy / red copper joint obtained by the new brazing process has finer and denser microstructure and higher shear strength; The wettability of zn78al22 solder on copper and aluminum and the shear strength of the joint are higher than those of zn92al8 solder joint.

2) The microstructure on the aluminum side of the brazing seam of 6063 aluminum alloy / red copper joint with zn75al25 new brazing process is white network distribution and precipitated first α Al is wrapped in black( α Al + β Zn) eutectic; The structure on the copper side is copper zinc aluminum solid solution interface compound, white block β Zn tissue and dendritic tissue, and the rest are a large number of black( α Al + β Zn) eutectic.

3) The new brazing process can effectively realize the welding of 6063 aluminum alloy / red copper joint. It has the advantages of convenient operation, high welding efficiency and high joint shear strength, up to 70.2 n / mm2.