Introduction of copper aluminum brazingBoth copper and aluminum are used to make electrical conductors, and the density of aluminum is one-third that of copper. Therefore, aluminum and copper forming connectors can reduce costs, reduce the quality of mechanical components, and exert their respective advantages....

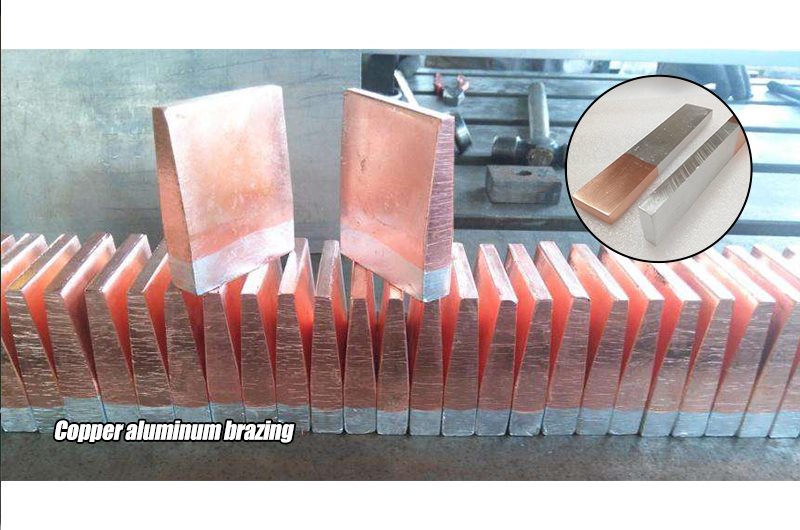

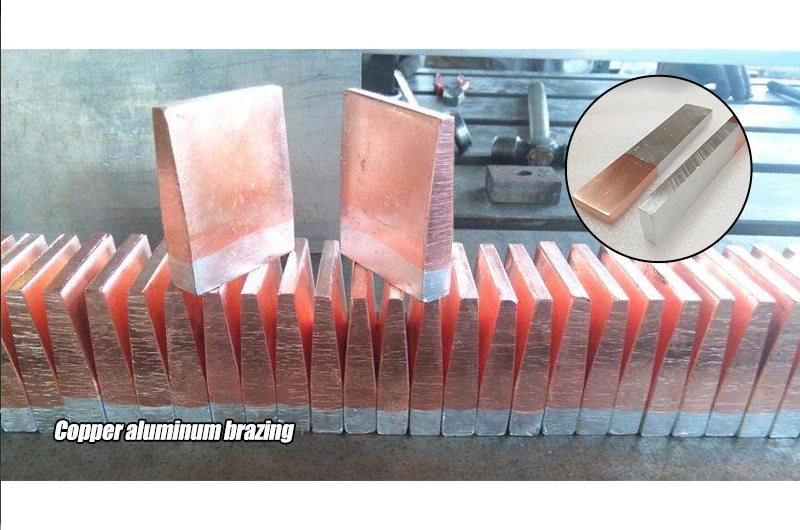

Introduction of copper aluminum brazing

Both copper and aluminum are used to make electrical conductors, and the density of aluminum is one-third that of copper. Therefore, aluminum and copper forming connectors can reduce costs, reduce the quality of mechanical components, and exert their respective advantages.

The method of copper aluminum brazing

- Welding process: brazing process, oxygen-propane (natural gas), oxygen-acetylene, petroleum liquefied gas flame brazing.

- Welding tools: gas cylinders with petroleum liquefied gas, brazing torches.

- Welding pretreatment

(1) Welding of copper and aluminum pipes

- Joint design: The unilateral gap of the joint should be controlled at 0.08 ~ 0.2mm, and the length of the weld is generally not more than 30mm.

- Surface treatment: Use lye or metal cleaning solution to clean the oil and other contaminants at the joint welding area, and then use a scraper (or coarse sandpaper, or copper brush, or wire brush) to scrape off the insulation layer on the surface of the joint welding area .

Note: It cannot be polished, because the solder is welded by capillary action, and it is not conducive to welding after polishing.

(2) Welding of copper bar and aluminum bar (or copper wire and aluminum wire):

Use lye or metal cleaning solution to clean the oil and other contaminants from the welding area, and then use a copper brush (or wire brush, or scraper, or coarse sandpaper) to scrape off the insulation layer on the surface of the joint welding area.

Note: It cannot be polished, because the solder is welded by capillary action, and it is not conducive to welding after polishing.

- Flame control and heating

(1) Selection of tools

It is preferred to use a uniformly heated air-assisted combustion welding torch (the welding torch is equipped with an air flow control valve and a rotating device, the flame is rotated through the welding tip, and the flame is evenly sprayed. This welding torch is sold by our company), and the reducing flame (natural gas, oil) is preferred liquefied gas burning flame).

(2) Heating method:

The flame should be soft and completely cover the welding area. The flame should be moved up and down and left and right with the connection area as the center, so that the connection area is heated evenly (when different metals are connected, more metal with good thermal conductivity should be heated. For example, when copper and aluminum are welded, more copper parts should be heated to ensure the connection. component temperature).

(3) Filling wire method:

while heating. The flux-cored wire can touch the workpiece in the connection area (the temperature of the workpiece melts the wire, and the welding effect is better). When it is found that the wire can be melted, the wire should be fed immediately, and the heating should be stopped to avoid over-burning and damage to the base metal. Feed the welding wire until the molten solder fills the weld (because the molten solder penetrates into the weld by capillary action, stop feeding the welding wire when it is visually seen that the weld is filled with solder. avoid unnecessary waste).

(4) Cooling method:

Remove the torch after welding to allow it to cool naturally.

Note: When welding, avoid the flame aiming at a certain point for a long time and the welding temperature should not exceed 630℃ to avoid burning the base metal.

Safety warning: Brazing work should wear protective clothing, protective gloves and protective glasses (or protective face shield), beware of liquid flux splashing on the skin and causing burns.

- Post-weld treatment:

No further treatment is required after cooling, the flux residue is visible but non-corrosive, does not absorb moisture and adheres firmly. If necessary, it is recommended to use physical methods to remove, such as using a metal brush to remove after soaking (if there is a small burr, it can be polished with fine sandpaper).