The flux in the molten state can partially dissolve and remove the oxide layer. As a result, the metal surface is cleaned with the flux, and the surface is suitable for 4045 aluminum alloy to connect metal workpieces. Therefore, adding flux is of utmost importance....

The flux in the molten state can partially dissolve and remove the oxide layer. As a result, the metal surface is cleaned with the flux, and the surface is suitable for 4045 aluminum alloy to connect metal workpieces. Therefore, adding flux is of utmost importance.

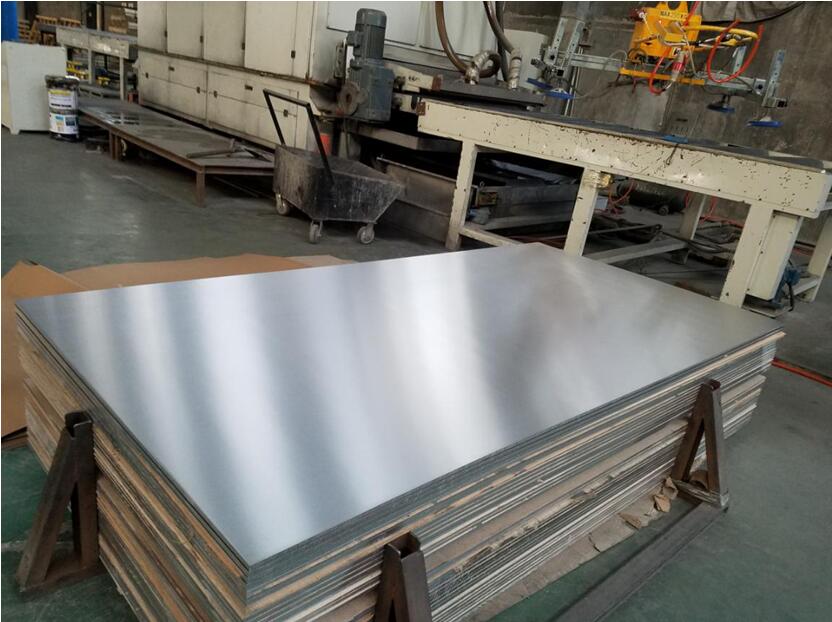

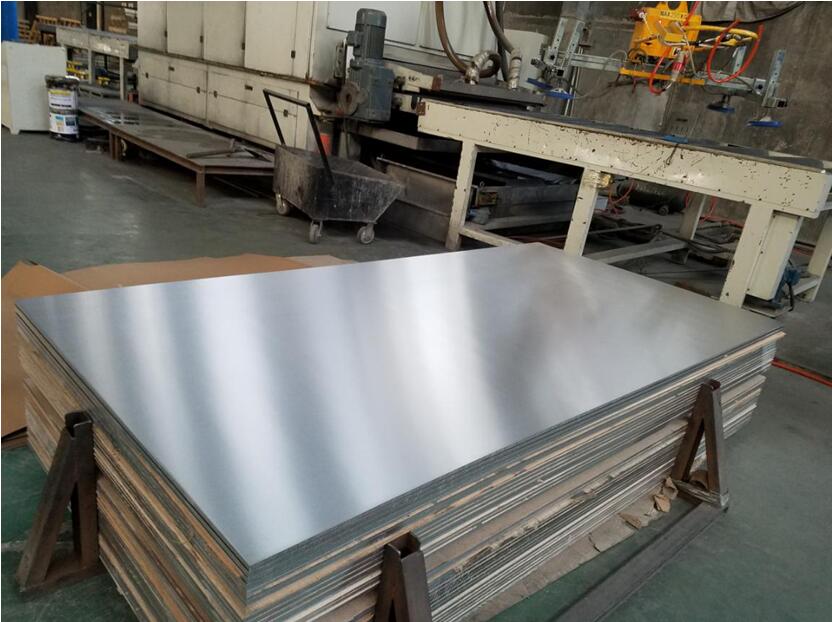

Choosing the right solder and solder alloy When soldering with solder, the typical 4045 aluminum alloy. There are many different types of solder alloys: the main solder alloy for brazing in the furnace contains silicon and the 4045 aluminum alloy with 9-11% silicon.

Select the size of the capillary action (gap).

The ideal link requires a suitable capillary gap between the components. Only when the gap is appropriate, the molten solder alloy can be spread by capillary action.

Filler welds must have 4045 aluminum alloy, but not excessive. There must be close contact between the two parts to be welded and there must be brazing filler metal around the weld. To emphasize this point in layman's terms: "The brazing filler metal can run, but it can't jump". The point of contact is the starting point of the capillary flow of the filler metal.